T: +86-186-8927-7942

E: kemp@hangjin-machinery.com

E: kemp@hangjin-machinery.com

No. 107 Changning Road, Tongjing Town, Jiangning District, Nanjing, Jiangsu, China

Views: 0 Author: Site Editor Publish Time: 2025-06-18 Origin: Site

Circular slitter blades are essential tools in industries like packaging, textiles, and metalworking. These precision blades ensure efficient and clean cuts, driving productivity. In this article, we'll explore the advancements and trends in circular slitter blades. You'll learn about the innovations that have shaped their design, materials, and manufacturing processes.

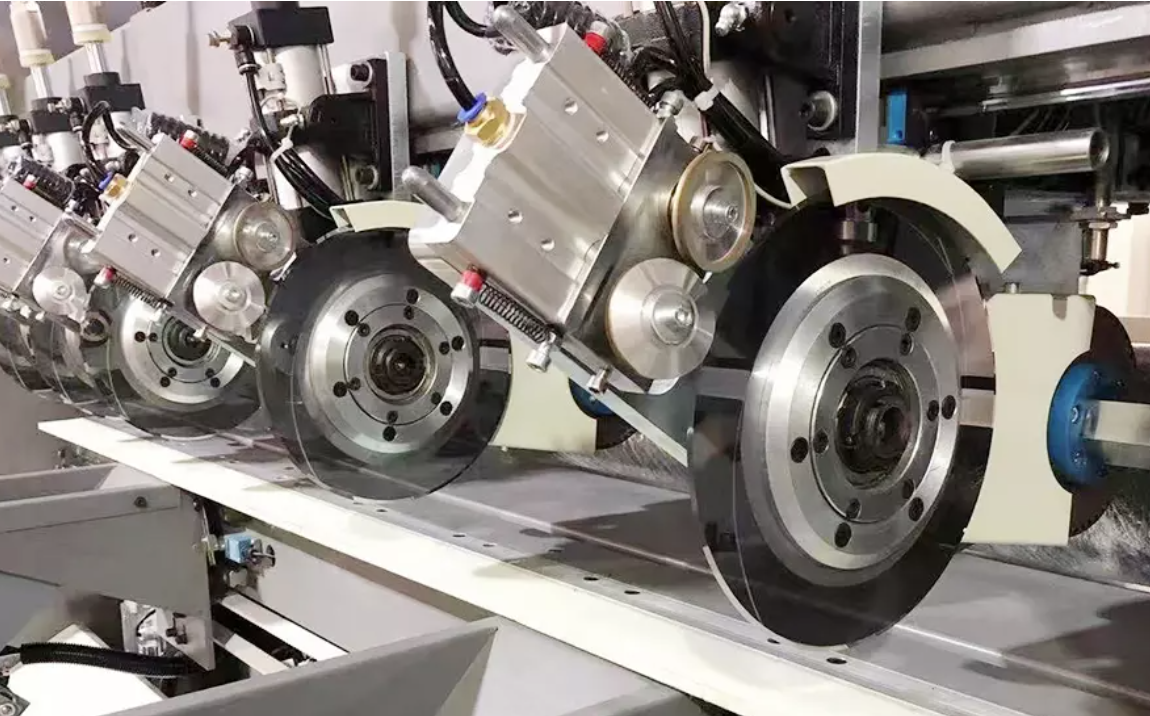

Circular slitter blades are precision cutting tools that operate in a rotary motion to slice through materials. They are designed to cut in a continuous, circular path, ensuring clean, uniform cuts. These blades are commonly used in industries requiring high levels of accuracy, where a sharp, consistent edge is crucial.

Circular slitter blades play an essential role in various industries:

Paper Conversion: Used to slice large rolls of paper into sheets of precise sizes.

Packaging: Ideal for cutting plastic films and cardboard for packaging purposes.

Printing: Help trim printed materials into desired shapes and sizes.

Food Processing: Commonly used for slicing meats, vegetables, and packaged goods.

Textiles: Essential for cutting fabrics into consistent widths and lengths.

Metalworking: Used for cutting metal sheets and strips with precision.

The importance of circular slitter blades lies in their ability to provide precise and efficient cuts. Their sharp, durable edges ensure minimal material wastage, higher productivity, and consistent results. Without these blades, industries like packaging and textiles would struggle to maintain the quality and consistency of their final products.

The origins of circular slitter knives trace back to ancient times. Initially, these blades were crafted from rudimentary materials like stone and bone. Early civilizations used these primitive tools for basic cutting tasks. As time progressed, metals such as copper and bronze replaced stone, offering better durability and sharper edges.

The Industrial Revolution in the 18th and 19th centuries marked a turning point in circular slitter blade development. Advancements in metallurgy allowed for mass production of more refined steel blades. These early steel blades were significantly sharper and more durable, improving cutting precision and efficiency in industries like paper processing and textiles. The availability of steel blades revolutionized manufacturing, enabling faster production and more consistent results.

In the 20th century, high-speed steel (HSS) and tungsten carbide emerged as major innovations in slitter blade materials. HSS provided better heat resistance and wear durability, ideal for high-speed applications. Tungsten carbide, known for its hardness and wear resistance, enabled the cutting of tougher materials like metals and plastics, significantly extending blade lifespans and reducing maintenance.

Today, circular slitter blades have evolved with cutting-edge materials like composite alloys and ceramic coatings. These materials offer a balance of hardness, toughness, and corrosion resistance. Precision manufacturing technologies like CNC machining allow for highly customized and intricate blade designs. Modern advancements continue to improve blade performance, focusing on longevity, efficiency, and adaptability to meet the demands of various industries.

In recent years, ergonomic design has become a key focus in circular slitter blade development. Ergonomic blades are designed to reduce operator fatigue by minimizing hand strain and improving handling. Features like comfortable grips, balanced weight distribution, and easy-to-operate mechanisms help improve comfort during long shifts. This innovation not only increases productivity but also enhances worker safety by reducing the risk of repetitive stress injuries.

Thin-kerf blades are another major innovation in circular slitter blade design. These blades are thinner than traditional ones, which results in less material waste during the cutting process. Their ability to cut efficiently with less force also reduces energy consumption, making them more environmentally friendly and cost-effective. Thin-kerf blades are particularly beneficial for industries where minimizing material waste is crucial, such as packaging and textiles.

Advancements in CAD (Computer-Aided Design) software and 3D printing have revolutionized custom blade production. Manufacturers can now design blades tailored to specific industry needs or unique cutting tasks. Using CAD software, manufacturers can create highly detailed and complex blade geometries that suit particular materials. 3D printing enables rapid prototyping, allowing for faster testing and iteration of blade designs. This customization ensures that circular slitter blades perform optimally for specialized applications.

The optimization of blade edge geometry is critical for enhancing cutting performance. By adjusting the edge angles, manufacturers can improve how the blade interacts with different materials. For example, sharper angles are ideal for cutting delicate materials like paper and film, ensuring a clean, smooth cut. On the other hand, stronger angles work better for tougher materials like metal, providing more force to make precise cuts without excessive wear. These design improvements lead to greater efficiency and blade longevity.

One of the most notable trends in the circular slitter blade market is the move towards laser cutting. Laser technology allows for incredibly precise cuts, reducing material waste and improving overall efficiency. Manufacturers are using lasers to create sharper and more accurate blades, ensuring smoother cuts and higher-quality results. This precision is essential in industries where even the smallest deviation can lead to significant losses, such as in packaging and textiles.

Artificial intelligence (AI) and robotics are increasingly being integrated into the manufacturing of circular slitter blades. AI helps optimize production processes by analyzing large amounts of data to improve cutting parameters. Meanwhile, robotics ensures that blade manufacturing is more consistent, reducing human error and increasing production speed. These technologies not only enhance blade performance but also improve quality control, ensuring that each blade meets the exact specifications needed for its application.

As environmental concerns continue to rise, there’s a strong push for eco-friendly materials and green manufacturing practices in the circular slitter blade industry. Manufacturers are now exploring sustainable materials for blade production, such as recyclable metals and biodegradable coatings. Additionally, energy-efficient manufacturing processes are being adopted to reduce the carbon footprint. These trends are driven by the growing demand for sustainable production methods in various sectors, including packaging, textiles, and metalworking.

Another trend driving the circular slitter blade market is the increasing demand for blades tailored to specific materials. Industries such as carbon fiber, composites, and advanced textiles require specialized blades that can handle these tougher, more complex materials. As manufacturers work with new materials, the need for custom blades designed to cut precisely and efficiently becomes more pronounced. Innovations in blade materials and design allow for better performance when cutting these unique materials, helping industries stay ahead of technological demands.

Advanced circular slitter blades ensure cleaner, more precise cuts, significantly reducing material waste. By maintaining sharp edges and high-quality design, these blades help manufacturers achieve consistent results, leading to more efficient production processes. Less waste translates directly to lower raw material costs, helping businesses save money while improving product quality.

Modern circular slitter blades are made from durable materials like high-speed steel, tungsten carbide, and advanced ceramic coatings. These materials extend the lifespan of the blades, reducing the frequency of replacements. As a result, businesses benefit from reduced downtime and fewer blade purchases, which ultimately lowers operational costs.

Innovative materials such as Titanium Nitride (TiN) and Diamond-Like Carbon (DLC) coatings help lower the maintenance needs of circular slitter blades. These coatings reduce friction, wear, and corrosion, enabling blades to maintain their sharpness and performance over time. This leads to fewer maintenance interventions, keeping production lines running smoothly and reducing overall maintenance costs.

Thin-kerf blades are designed to minimize material waste and reduce power consumption during cutting. These blades require less force to make cuts, meaning production processes use less energy. By cutting through materials more efficiently, thin-kerf blades reduce energy costs, contributing to a more sustainable and cost-effective manufacturing operation.

The future of circular slitter blades will see the integration of Internet of Things (IoT) technology. This will allow real-time monitoring of blade performance, enabling predictive maintenance. Sensors will track blade wear, temperature, and cutting precision, alerting operators when maintenance is needed before a failure occurs. This will minimize downtime, reduce costs, and improve overall operational efficiency.

Robotics and automation will continue to revolutionize the production of circular slitter blades. Automated systems will streamline manufacturing, increasing speed and precision. Robotic arms will handle delicate processes like grinding, coating, and assembly, improving consistency and reducing human error. As these technologies advance, we can expect even greater efficiency and higher-quality blades produced at a faster pace.

Additive manufacturing (3D printing) will play a major role in the future of circular slitter blades. This technology allows manufacturers to create highly customized and complex blade designs tailored to specific materials or applications. 3D printing offers faster prototyping and the ability to produce specialized blades without the long lead times of traditional manufacturing methods, making it ideal for industries requiring unique blade features.

Sustainability will be a key focus in the development of circular slitter blades. There will be an increased shift towards eco-friendly materials and processes that reduce environmental impact. This includes using recyclable materials for blade production, optimizing energy usage during manufacturing, and reducing waste through advanced cutting technologies. As companies prioritize green initiatives, sustainable blade production will become the norm, aligning with broader environmental goals in the manufacturing sector.

In recent years, circular slitter blades have seen advancements in materials, cutting technology, and design. Innovations like laser cutting, AI, and precision coatings have improved performance and durability. Looking ahead, smart technology and sustainability will drive the future of slitter blades. AI, IoT, and eco-friendly materials are set to enhance blade efficiency and reduce environmental impact. Explore advanced circular slitter blades to meet your business needs and stay ahead in the industry.

A: Circular slitter blades are used for precision cutting in industries like paper conversion, packaging, textiles, and metalworking.

A: Laser cutting improves the precision of slitter blades, reducing material waste and enhancing cutting efficiency.

A: Modern blades are made from materials like high-speed steel (HSS), tungsten carbide, and advanced ceramics for better durability.

A: AI and robotics improve precision, speed, and quality control in manufacturing, leading to better-performing blades.

A: Thin-kerf blades reduce waste and energy consumption, making them more efficient for cutting delicate or tough materials.