T: +86-186-8927-7942

E: kemp@hangjin-machinery.com

E: kemp@hangjin-machinery.com

No. 107 Changning Road, Tongjing Town, Jiangning District, Nanjing, Jiangsu, China

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

Ever struggled to cut metal, wood, or plastic precisely? Circular blades might be your solution. These versatile tools transform cutting tasks, but choosing the right blade is crucial for safety and efficiency. In this post, you'll learn about different circular blades, their features, and how to select the best one for your needs.

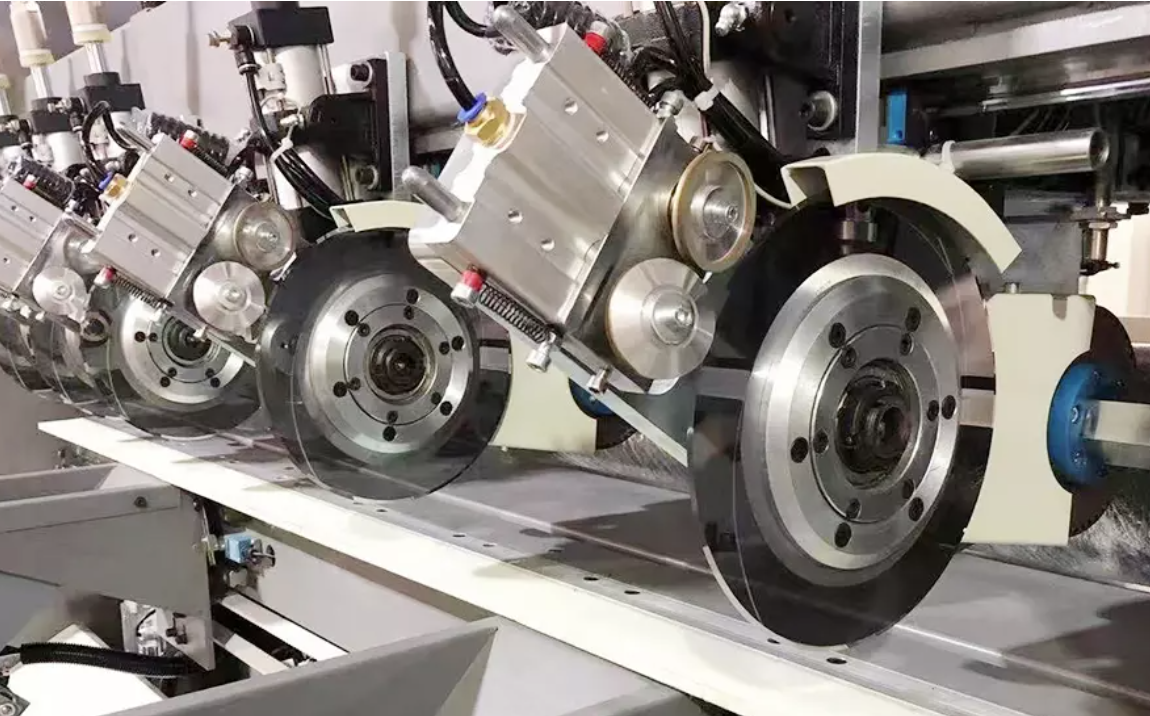

Circular blades are round cutting tools designed to rotate at high speeds, slicing through materials like metal, wood, and plastic. They fit onto power saws such as handheld circular saws, table saws, or miter saws. The blade’s teeth cut the material as it spins, making precise or rough cuts depending on the blade type.

There are several types of circular blades tailored for specific uses:

Rip Blades: Fewer, larger teeth designed for cutting along the grain of wood. They remove material fast but with a rougher finish.

Crosscut Blades: More teeth with alternating bevels for smooth cuts across the grain.

Combination Blades: Mix of rip and crosscut teeth for versatile use.

Specialty Blades: Designed for unique tasks like dado cuts or cutting specific materials such as metal or plastic.

Each blade type suits different cutting needs, ensuring optimal performance and safety.

When selecting a circular blade, several features impact cutting quality and compatibility:

Blade Diameter: Must match the saw’s specifications. Common sizes range from 4.5 inches to 12 inches or more. Larger diameters allow deeper cuts.

Bore Size: The hole at the blade’s center that fits onto the saw’s arbor. Correct bore size ensures secure mounting.

Number of Teeth: More teeth yield smoother cuts; fewer teeth cut faster but rougher. For example, blades with 24 teeth are good for quick rip cuts, while blades with 60-80 teeth provide fine finishes.

Tooth Geometry: Shape and angle of teeth affect cutting efficiency and finish. Flat-top teeth excel in ripping, while alternate top bevel teeth handle crosscutting.

Kerf Width: The thickness of the cut the blade makes. Thin kerf blades remove less material and require less power but may be less stable.

Rake Angle: The angle of the tooth face relative to the blade's center affects cutting aggressiveness. Positive rake angles cut faster; negative rake angles provide smoother, slower cuts.

Blade durability and cutting ability depend heavily on construction materials:

High-Speed Steel (HSS): Common and affordable, good for basic cutting tasks but dulls faster.

Carbide-Tipped Teeth: Harder than steel, stay sharp longer, ideal for hardwood, metal, and plastic cutting. Require special sharpening tools.

Tungsten Carbide: A premium carbide variant offering superior wear resistance and heat tolerance.

Coatings: Some blades have coatings like titanium or cobalt to reduce heat buildup and extend blade life.

The blade body is usually made from hardened steel alloys for strength and vibration reduction. Expansion slots cut into the blade allow heat expansion without warping, maintaining accuracy.

Choosing the right circular blade depends largely on the material you plan to cut. Each material—metal, wood, plastic—has unique properties requiring specific blade designs for clean, efficient cuts. Let’s explore the best blade types for each material and also look at versatile multi-purpose options.

Cutting metal demands blades built tough to handle hardness and heat. Metal blades usually have:

High tooth count: Around 60 to 80 teeth for smooth, burr-free cuts.

Tooth geometry: Triple Chip Grind (TCG) teeth, alternating between flat and trapezoidal shapes, reduce chipping.

Materials: Carbide-tipped teeth for durability and heat resistance.

Blade body: Hardened steel with expansion slots to prevent warping.

These blades suit non-ferrous metals like aluminum, brass, and softer steels. For harder metals, blades with fewer teeth (30 to 50) and specialized coatings help maintain sharpness and reduce heat buildup.

Example: A 10-inch carbide-tipped blade with 60 teeth and TCG design works well for aluminum sheets.

Wood blades vary depending on the type of cut and wood species:

Rip blades: Fewer teeth (around 24-30), flat-top teeth, designed for fast cuts along the grain.

Crosscut blades: More teeth (60-80), alternate top bevel teeth, for smooth cuts across the grain.

Combination blades: Intermediate tooth count (40-50), mix of tooth designs for versatile use.

For softwoods, blades with more teeth and thin kerfs reduce tear-out and sap buildup. Hardwoods require blades with fewer teeth and thicker plates for stability and deeper cuts.

Carbide-tipped teeth are standard for wood blades, offering long-lasting sharpness.

Example: A 7-1/4 inch 40-tooth combination blade suits general woodworking projects.

Plastic cutting needs blades that minimize cracking, melting, or chipping:

High tooth count: Usually 60-80 teeth for smooth, precise cuts.

Tooth design: Triple Chip Grind (TCG) for clean edges.

Blade material: Carbide tips to maintain sharpness and reduce friction.

Blade speed: Lower RPMs help prevent heat buildup.

Using blades designed for plastics prevents damage and improves safety. Avoid blades with aggressive teeth that can chip or crack delicate plastics like acrylic or PVC.

Example: A 10-inch carbide-tipped blade with 80 teeth and TCG is excellent for cutting acrylic sheets.

Multi-purpose blades combine features to handle wood, plastic, and some metals. They often have:

Moderate tooth count: Around 40-50 teeth.

Mixed tooth geometry: Groups of alternate bevel and flat-top teeth.

Carbide tips: For durability across materials.

Negative rake angle: To reduce kickback and improve control.

While not optimized for heavy metal cutting, these blades offer convenience for DIYers and professionals tackling varied materials without swapping blades constantly.

Example: A 10-inch 50-tooth multi-material blade works well for projects mixing wood, plastic, and light metal.

Choosing the right circular blade is key for clean cuts and safety. First, match the blade diameter to your saw. Using a blade too large or small risks damage or injury. Check your saw’s manual for the exact size.

Next, consider the blade material. Carbide-tipped blades last longer and cut tougher materials better than high-speed steel, though they cost more. For metal, wood, or plastic, carbide tips are usually best.

Teeth count matters too. Fewer teeth mean faster, rougher cuts. More teeth give smoother, cleaner cuts but cut slower. For example, a blade with 24 teeth suits quick ripping through wood, while 60 to 80 teeth work well for fine crosscuts or plastics.

Tooth shape or geometry also affects cutting. Flat-top teeth cut aggressively, ideal for ripping wood. Alternate top bevel teeth slice cleaner across wood grain or plastic. Triple chip grind teeth suit hard metals and plastics, reducing chipping.

Blade kerf—the width of the cut—affects power needed and waste. Thin kerf blades waste less material and require less power but may flex more. Full kerf blades are sturdier, better for heavy-duty cuts.

Different materials need specific blades for best results:

Metal: Use blades with high tooth count (60-80 teeth) and triple chip grind teeth. Carbide tips resist heat and wear. For harder metals, fewer teeth (30-50) with special coatings help.

Wood: Rip blades have fewer teeth (24-30) and flat-top teeth for fast cuts along the grain. Crosscut blades have more teeth (60-80) and alternate bevel teeth for smooth cuts across grain. Combination blades balance both.

Plastic: High tooth count (60-80) and triple chip grind teeth prevent cracking. Carbide tips reduce friction and stay sharp.

Multi-purpose: Moderate tooth count (40-50) with mixed tooth shapes handle wood, plastic, and light metal. Great for DIYers needing flexibility.

Blade diameter sets cut depth and must fit your saw. Larger diameter blades cut deeper but need more power.

Teeth count influences cut quality and speed. Low tooth counts cut fast but rough. High tooth counts give smooth finishes but slow down cutting. Choose based on your project’s finish needs.

Here’s a quick guide:

| Material | Teeth Count | Tooth Type | Blade Diameter (inches) |

|---|---|---|---|

| Wood (Rip) | 24-30 | Flat-top | 7-1/4 to 12 |

| Wood (Cross) | 60-80 | Alternate top bevel | 7-1/4 to 12 |

| Metal | 30-80 | Triple chip grind | 7-1/4 to 12 |

| Plastic | 60-80 | Triple chip grind | 7-1/4 to 12 |

| Multi-purpose | 40-50 | Mixed | 7-1/4 to 12 |

If cutting hardwood furniture parts, a 10-inch blade with 40-50 teeth and carbide tips works well. For aluminum sheets, a 10-inch blade with 60 teeth and triple chip grind teeth is better.

Proper maintenance and care keep your circular blades sharp, safe, and long-lasting. Neglecting this can lead to dull cuts, increased wear, and even accidents. Here’s how to care for your blades effectively.

Unplug and Remove the Blade: Always disconnect the saw before removing the blade. Use the correct wrench or tool to safely take the blade off.

Remove Debris and Resin: Sawdust, pitch, and resin build-up can gum up teeth and reduce cutting efficiency. Use a soft brush or cloth to clear them away.

Use Cleaning Solutions: For stubborn residue, soak the blade in a mild cleaning solution made for saw blades or a mix of water and a small amount of dish soap. Avoid harsh chemicals that can damage carbide tips.

Dry Thoroughly: After cleaning, dry the blade completely to prevent rust.

Store Properly: Keep blades in a dry, cool place. Use blade cases or hang them on hooks to avoid damage. Avoid stacking blades directly on top of each other without protection.

Sharpen Regularly: Dull blades cause rough cuts and strain your saw. Sharpen teeth evenly using a diamond file or a professional sharpening service. Count strokes per tooth to keep uniform sharpness.

Check for Damage: Look for chipped or missing teeth. Replace blades if damage is severe.

Balance the Blade: An unbalanced blade vibrates and can cause inaccurate cuts or damage. Use a blade balancer to check. If unbalanced, have it professionally corrected.

Frequency: Sharpen and balance blades after every few hours of heavy use. For home use, check every few months or when cuts become rough.

Wear Protective Gloves: Blade teeth are sharp. Gloves protect hands from cuts during cleaning and sharpening.

Work in a Well-Lit Area: Good lighting helps spot damage or buildup.

Secure the Blade: Use a vise or clamp when sharpening to prevent slipping.

Keep Tools Organized: Use proper sharpening tools and keep them in good condition to avoid accidents.

Follow Manufacturer Guidelines: Some blades require specific care or sharpening angles. Always check instructions.

Using circular blades safely is crucial to protect yourself and others. These blades spin at high speeds and can cause serious injury if handled carelessly. Let’s cover essential safety gear, operating tips, and common mistakes to avoid.

Before you start cutting, gear up properly:

Eye Protection: Always wear safety goggles or glasses. Flying debris or sparks can damage your eyes.

Hearing Protection: Circular saws are loud. Use earplugs or earmuffs to protect your hearing.

Gloves: Wear snug-fitting gloves to protect your hands from sharp blade edges and splinters. Avoid loose gloves that might get caught.

Dust Mask or Respirator: Cutting wood, metal, or plastic creates dust and particles. A dust mask helps prevent inhaling harmful substances.

Sturdy Footwear: Wear closed-toe shoes or boots to protect feet from falling tools or materials.

Proper Clothing: Avoid loose clothing, jewelry, or anything that could get caught in the blade. Tie back long hair.

Safe operation depends on the right habits:

Read the Manual: Understand your saw’s features, blade compatibility, and safety instructions.

Check the Blade: Inspect for damage, dullness, or warping before use. Replace or sharpen as needed.

Secure Your Workpiece: Clamp or firmly hold the material to prevent movement during cutting.

Maintain a Firm Grip: Hold the saw with both hands and keep a balanced stance.

Cut Away From Your Body: Always position yourself so the blade moves away from you.

Avoid Distractions: Stay focused; never use the saw when tired or under the influence.

Keep the Area Clear: Remove obstacles and keep bystanders, especially children, at a safe distance.

Use Guards and Safety Features: Never remove blade guards or safety switches.

Allow Blade to Reach Full Speed: Before cutting, let the blade spin up to speed for a smoother, safer cut.

Avoid Overreaching: Keep your balance and avoid stretching too far while cutting.

Unplug When Adjusting: Disconnect power before changing blades or making adjustments.

Knowing what not to do prevents accidents:

Using the Wrong Blade: Don’t use a blade meant for wood on metal or plastic. It risks kickback and poor cuts.

Forcing the Saw: Let the blade do the work. Pushing too hard causes binding, overheating, and kickback.

Cutting Unstable Material: Loose or warped workpieces can shift unexpectedly.

Ignoring Blade Condition: Dull or damaged blades increase kickback risk and reduce cut quality.

Neglecting Maintenance: Dirty or unbalanced blades can wobble dangerously.

Improper Storage: Storing blades improperly can cause damage and rust, leading to unsafe use.

Not Wearing Safety Gear: Skipping eye protection or gloves invites injury.

Circular blades are essential for cutting metal, wood, and plastic efficiently. Selecting the right blade involves considering material type, blade diameter, and teeth count. Prioritizing safety and regular maintenance ensures optimal performance and longevity. For high-quality blades, consider Nanjing Hangjin Machinery Equipment Co., Ltd., known for durable, versatile products that enhance cutting precision and safety.

A: Circular blades are used for cutting materials like metal, wood, and plastic.

A: Rip blades have fewer teeth for fast cuts along the grain, while crosscut blades have more teeth for smooth cuts across the grain.

A: Carbide-tipped teeth stay sharp longer and are ideal for cutting tough materials like hardwood and metal.