T: +86-186-8927-7942

E: kemp@hangjin-machinery.com

E: kemp@hangjin-machinery.com

No. 107 Changning Road, Tongjing Town, Jiangning District, Nanjing, Jiangsu, China

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

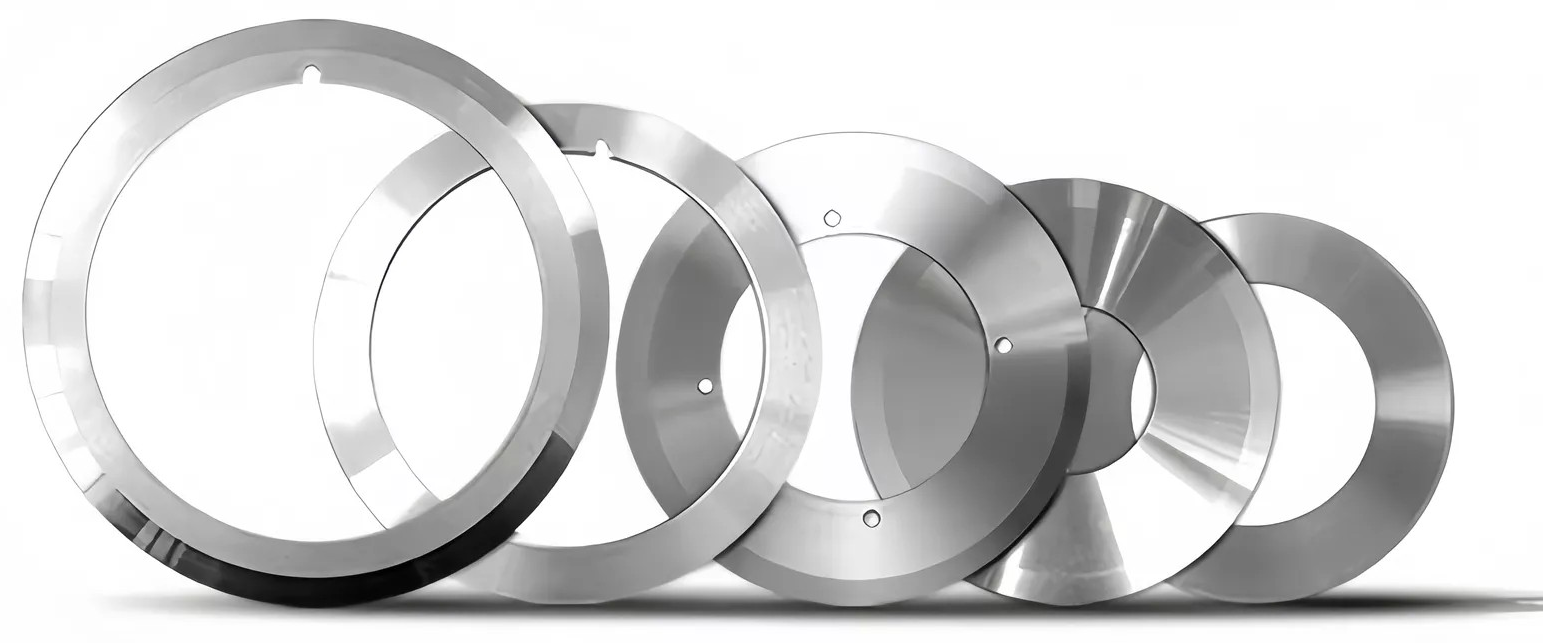

Have you ever wondered how industries achieve precision cuts in materials like steel or textiles? Circular blades are key. Selecting the right circular blade for industrial applications is crucial for efficiency and quality. In this guide, you'll learn about different blade types, applications, and factors to consider for optimal performance.

When selecting a circular blade for industrial use, knowing the types available helps you match the blade to your needs. Circular blades differ mainly by their material and construction, which affects durability, cutting speed, and the materials they handle best.

High-Speed Steel blades are a popular choice for many industrial applications. Made from a special alloy that retains hardness at high temperatures, HSS blades cut through metals like steel and aluminum efficiently. They offer good toughness and resist wear during continuous use.

Advantages include:

Cost-effective for general metal cutting

Can handle moderate cutting speeds

Easier to sharpen than carbide blades

However, they wear out faster than carbide-tipped blades when cutting harder or abrasive materials.

Carbide-tipped blades combine the toughness of steel with the hardness of carbide inserts on the teeth edges. The carbide tips provide superior wear resistance and maintain sharpness longer than HSS blades. These blades are ideal for cutting hard metals, composites, and abrasive materials.

Key benefits:

Longer blade life and less frequent sharpening

Faster cutting speeds possible

Cleaner cuts with less burr formation

They tend to cost more upfront but reduce downtime and replacement costs over time.

Solid carbide blades are made entirely from tungsten carbide, a very hard and wear-resistant material. These blades excel in high-precision, high-volume cutting of tough materials such as hardened steel, composites, and non-ferrous metals.

Features include:

Exceptional hardness and edge retention

High resistance to heat and wear

Suitable for automated, high-speed cutting systems

They are more brittle than steel blades and require careful handling to avoid chipping.

Some circular blades are designed for niche industrial uses. These specialty blades may have unique tooth geometries, coatings, or materials tailored to particular tasks such as cutting plastics, textiles, or food products. Examples include:

Serrated blades for cutting fibrous materials

Coated blades with anti-corrosion or low-friction surfaces

Ceramic-tipped blades for non-metallic materials

Choosing a specialty blade ensures optimal performance and extends blade life in specialized environments.

Circular blades are essential tools across many industries, prized for their precision, efficiency, and versatility. Their design allows for fast, clean cuts, making them ideal for a variety of industrial tasks. Let’s explore the main applications where circular blades excel.

Cutting is the primary function of circular blades, used to slice through materials quickly and accurately. Industries rely on these blades to handle diverse materials such as metals, plastics, textiles, and wood. Circular blades provide:

Fast, consistent cuts that improve productivity

Minimal material waste through precision cutting

Clean edges that reduce the need for secondary finishing

Trimming involves refining edges or removing excess material. Circular blades with fine teeth and sharp edges help achieve smooth, precise trims on fabrics, leather, rubber, and sheet metals. This enhances the quality and appearance of finished products.

Slitting refers to cutting materials into narrow strips, often used in packaging, paper, and plastic industries. Circular blades designed for slitting typically have beveled or toothless edges to create clean, burr-free cuts. They are also called slitter knives and are vital for:

Cutting films, foils, and paper into precise widths

Processing plastic sheets or rubber into strips

Enabling fast, continuous production runs

Slicing involves cutting materials into uniform pieces, such as food products or metal bars. Circular blades provide consistent, repeatable slices, essential for industries like food processing and metal fabrication. Their rotary motion ensures smooth cuts even on slippery or dense materials.

Perforating means creating a series of small holes or cuts to make materials easier to tear or fold. Circular blades with specialized tooth geometry are perfect for perforating packaging materials, plastics, or paper. This application improves product functionality and user convenience.

Scoring involves making shallow cuts or grooves to guide folding or breaking. Circular blades can score materials like glass, stone, metal, or cardboard with high accuracy. Proper scoring prevents unwanted cracks or breaks, crucial in packaging and manufacturing.

Circular blades adapt to many industry needs beyond general cutting. Some examples include:

Food processing: Slicing meats, cheeses, fruits, and vegetables with hygienic, corrosion-resistant blades

Textile and leather: Trimming and splitting fabrics or leather for apparel and upholstery

Plastic and rubber: Slitting and shaping components for automotive or consumer goods

Metalworking: Cutting steel sheets, tubes, or aluminum profiles with carbide-tipped blades for durability

Paper and packaging: Perforating, scoring, and trimming cardboard or films for boxes and wraps

Each industry requires blades tailored to its materials and processes. Selecting the right blade type, tooth design, and material ensures optimal performance and longer blade life.

Selecting the right circular blade for industrial use means balancing several key factors. Each one influences cutting quality, blade life, and overall efficiency. Let’s break down the most important considerations to help you make the best choice.

The type of material you plan to cut is the single most critical factor. Different materials require different blade characteristics:

Metals: Hard metals like steel or aluminum need blades made from high-speed steel or carbide-tipped edges for durability and sharpness.

Plastics and composites: Softer materials may require blades with finer teeth to prevent chipping and melting.

Wood and textiles: Blades with specific tooth geometries reduce splintering and fraying.

Food products: Stainless steel or corrosion-resistant blades ensure hygiene and prevent rust.

Understanding your material’s hardness, thickness, and abrasiveness guides you toward the right blade type and tooth design.

Blade size must match your machine for safe, efficient operation. Key dimensions include:

Diameter: Choose the smallest diameter that fits your machine to maximize blade rigidity and reduce vibration.

Thickness: Should be proportional to diameter to ensure stability and precise cutting.

Bore (arbor hole): Must fit securely on the machine spindle to avoid wobbling.

Using a blade with incorrect dimensions can cause poor cuts, excessive wear, or even safety hazards.

Tooth shape and number directly affect cut quality and speed:

Tooth count: More teeth produce smoother cuts but cut slower. Fewer teeth cut faster but leave rougher edges.

Tooth shape: Options include flat-top, alternate top bevel, triple-chip grind, and more. Each suits different materials and cutting styles.

Chamfering: Some teeth have chamfers or chip breakers to reduce heat and improve chip removal.

Selecting the right tooth geometry balances cutting speed, finish quality, and blade longevity.

Coatings enhance blade performance and durability:

Wear resistance: Coatings like titanium nitride extend blade life by reducing abrasion.

Reduced friction: Low-friction coatings help blades cut cooler and faster.

Corrosion protection: Essential for blades used in moist or corrosive environments.

Residue prevention: Some coatings prevent material buildup on the blade, maintaining sharpness.

Choosing the right coating depends on your material and operating conditions.

Choosing the right material for your circular blade is crucial. It affects cutting efficiency, blade life, and the quality of the cut. Different materials suit different industrial tasks, depending on hardness, corrosion resistance, and wear properties. Let’s explore the common materials used in circular blades and their benefits.

High-carbon steel is a popular choice for circular blades, especially where toughness and sharpness are needed. It contains a higher percentage of carbon than regular steel, which increases hardness and edge retention. This material works well for cutting softer metals, wood, and plastics.

Benefits:

Durable and holds a sharp edge for repeated use

Easier to sharpen than carbide blades

Cost-effective for many industrial applications

Considerations:

Less resistant to corrosion, so it may rust if exposed to moisture

Not ideal for very hard or abrasive materials

Stainless steel blades offer excellent corrosion resistance, making them ideal for moist or food-related environments. They combine iron, carbon, and chromium, which prevents rust and maintains hygiene standards.

Benefits:

Resists corrosion and staining

Suitable for food processing, packaging, and medical industries

Easy to clean and maintain

Considerations:

Generally softer than high-carbon steel or carbide, so edges may dull faster

Best for cutting softer materials or where hygiene is critical

Solid carbide blades are made entirely from tungsten carbide, a very hard and wear-resistant material. They excel in high-precision, high-volume cutting of tough materials like hardened steel, composites, and non-ferrous metals.

Benefits:

Exceptional hardness and edge retention

High resistance to heat and wear

Ideal for automated, high-speed cutting systems

Considerations:

More brittle than steel blades; careful handling needed to avoid chipping

Higher initial cost, but longer life reduces replacement frequency

Ceramic blades, made primarily from zirconia ceramic, offer unique advantages. They are extremely hard, maintain sharpness for a long time, and don’t corrode because they contain no iron.

Benefits:

Very wear-resistant and maintain sharpness

Non-corrosive and ideal for food or chemical processing

Lightweight and heat-resistant

Considerations:

Brittle and prone to chipping or breaking if mishandled

Typically used for specialized applications rather than general cutting

| Material | Hardness | Corrosion Resistance | Best For | Cost |

|---|---|---|---|---|

| High-Carbon Steel | Moderate | Low | Wood, softer metals, plastics | Low |

| Stainless Steel | Moderate | High | Food, packaging, moist environments | Moderate |

| Solid Carbide | Very High | Moderate | Hardened metals, composites | High |

| Ceramic | High | Very High | Food, chemicals, specialized | High |

Selecting the ideal circular blade configuration depends largely on the material and application. Different edge types and tooth geometries suit different cutting needs. Matching these features ensures efficient cutting, longer blade life, and better product quality.

Circular blades come with various edge styles, each designed for specific cutting tasks:

Square Edge: Provides a strong, durable edge ideal for general-purpose cutting. It delivers clean cuts on harder materials like metals.

Single-Bevel Sharp: Features one angled edge, perfect for slicing or scoring where a precise, sharp cut is required.

Single-Bevel Blunt: Has one angled but blunt edge, useful for trimming or cutting softer materials without tearing.

Double-Blunt: Both edges are blunt, offering durability for rough cutting or splitting tasks.

Double-Sharp: Both edges are sharp, suitable for materials needing clean, precise cuts on both sides.

Double-Single (Sharp or Blunt): Combines single bevel edges on both sides, balancing sharpness and durability for versatile applications.

Choosing the right edge type depends on the material’s hardness, thickness, and the finish quality needed.

Tooth shape and arrangement influence cut speed, smoothness, and chip removal:

Standard V: Simple triangular teeth that work well for general cutting.

Vari-Depth V: Teeth vary in height, helping reduce vibration and improve smoothness.

Hi/Lo V: Alternating high and low teeth for fast cutting and efficient chip clearance, ideal for plastics and wood.

Scalloped: Rounded teeth edges minimize material damage, good for delicate materials.

Peg Style: Small, rounded teeth for fine trimming and smooth finishes.

Slant Tooth: Angled teeth designed to reduce cutting forces and improve surface finish.

Double-Double Sharp: Complex tooth design for high precision and clean cuts on tough materials.

Each geometry suits different materials and cutting conditions. For example, a Hi/Lo V tooth pattern excels at cutting soft plastics quickly, while a scalloped tooth blade protects fragile fabrics from tearing.

Understanding your cutting needs helps in selecting the best blade configuration:

Cutting Hard Metals: Use square edge blades with carbide-tipped teeth and standard or slant tooth geometry for durability and clean cuts.

Slicing Soft Materials: Single-bevel sharp edges combined with scalloped or peg-style teeth reduce tearing and improve finish.

Trimming or Scoring: Single-bevel blunt edges with fine tooth geometry provide precise control without damaging material.

Splitting or Rough Cuts: Double-blunt edges with coarse teeth offer strength and longevity for tough materials.

High-Speed Production: Hi/Lo V tooth geometry paired with sharp edges balances speed and cut quality.

Proper blade configuration also considers machine compatibility. The blade’s thickness and diameter must suit your equipment to avoid vibration and ensure safety.

Selecting the right circular blade for industrial applications involves understanding blade types, materials, and configurations. Consider the material to be cut, blade dimensions, tooth geometry, and coatings for optimal performance. For further assistance, consult experts or manufacturers like Nanjing Hangjin Machinery Equipment Co., Ltd. to ensure you choose the best blade for your needs. Their products are designed to enhance efficiency and productivity in various industrial settings, providing exceptional value and reliability.

A: High-Speed Steel (HSS), Carbide-Tipped, Solid Carbide, and Specialty Blades.

A: Carbide-tipped blades are ideal for cutting hard metals due to their wear resistance.

A: Material to be cut, blade dimensions, tooth geometry, and blade coatings.

A: They offer excellent corrosion resistance and maintain hygiene standards.