T: +86-186-8927-7942

E: kemp@hangjin-machinery.com

E: kemp@hangjin-machinery.com

No. 107 Changning Road, Tongjing Town, Jiangning District, Nanjing, Jiangsu, China

Views: 0 Author: Site Editor Publish Time: 2025-06-13 Origin: Site

Circular saw blades are essential tools in woodworking and construction, but over time, they can become dull and inefficient. A dull blade not only slows down your work but can also be dangerous, leading to overheating, rough finishes, and even kickbacks. If you're wondering how to sharpen a circular saw blade effectively, you've come to the right place. In this guide, we'll explore various methods to sharpen your circular saw blades, ensuring they perform optimally and safely.

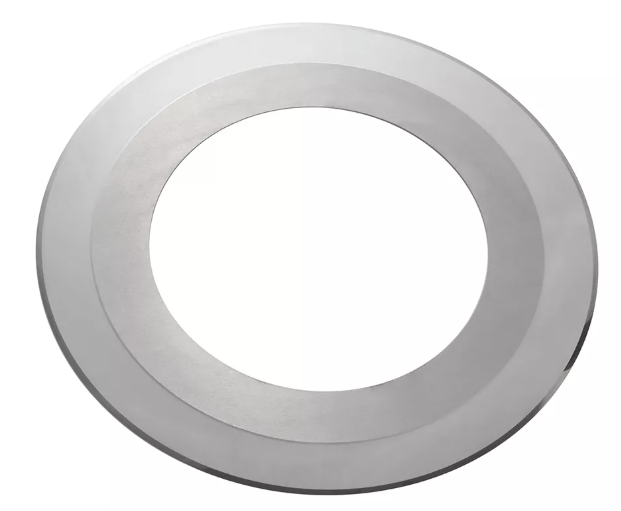

Before diving into the sharpening process, it's crucial to understand the types of circular saw blades available. Generally, these blades are either masonry blades or carbide-tipped blades.

Masonry Blades: These are typically used for cutting concrete, stone, or cinder blocks. They have a diamond-encrusted edge and are less expensive but wear out quickly when cutting through wood or other softer materials.

Carbide-Tipped Blades: These blades are more durable and can cut through a variety of materials, including wood, metal, and plastic. The teeth are made of a hard carbide material, providing a longer lifespan. They cut with both the face and sides of the blade, which makes them more efficient.

Knowing when to sharpen your blade is vital for maintaining its efficiency and safety. Here are some signs that indicate it's time to sharpen your circular saw blade:

Slower Progress: If the blade rotates more slowly and struggles to cut through materials, it might be dull.

Vibrations: Unusual vibrations during operation can indicate the blade has become uneven.

Poor Cuts: Frayed edges or rough finishes are common signs of a dull blade.

Smoke or Burn Marks: Excessive heat generation leading to burned marks on the cuts is a telltale sign of dullness.

To sharpen a circular saw blade, you'll need a few essential tools. Depending on the method you choose, these tools may vary:

Bench Vice or Clamps: To secure the blade in place for a stable sharpening process.

Oil or Lapping Fluid: Helps prolong the life of your sharpening stick or sandpaper.

Sharpening Stick or Sandpaper: Used to sharpen the blade's teeth, often necessary for hand sharpening.

Files: A flat file for trimming teeth and a triangular file for sharpening.

Additionally, you might want to use a Dremel Tool or Diamond Blade for more precision in sharpening, especially if you're dealing with carbide-tipped blades.

Sharpening a circular saw blade by hand is a cost-effective method, suitable for blades that are not carbide-tipped. Here's a step-by-step guide:

First, ensure the circular saw is unplugged. Remove the blade using a wrench or spindle lock, depending on your saw model.

Place the blade in a bench vice or secure it with clamps. This prevents vibrations and ensures stability during the sharpening process. Proper clamping is essential for safety.

Use a marker to mark the first tooth you plan to sharpen. This helps you track your progress and avoid over-sharpening. It also ensures that you're sharpening every tooth evenly.

Use a flat file to flatten the tips of the teeth, ensuring they are all the same height. This step corrects any unevenness caused by frequent use. Make sure you file each tooth with a steady hand to maintain uniformity.

Using pliers, set the teeth alternately to the left and right. This prevents the blade from getting caught in the material and ensures a smooth cut. This step is crucial for maintaining proper cutting performance.

With a triangular file, sharpen each tooth by filing in long, smooth strokes. Match the original angle of the tooth to maintain consistency. Typically, the angle will be between 10° and 20° depending on the type of blade. Keep your strokes consistent for optimal results.

Once all teeth are sharpened, reinstall the blade in the circular saw. Ensure it fits tightly to avoid imbalance. Any imbalance can cause unnecessary vibrations and affect the blade's cutting ability.

Perform a test cut on a wooden block to check the blade's sharpness. Look for smooth cuts, minimal splintering, and quiet operation. If the blade still struggles or produces rough cuts, you may need to revisit the sharpening process.

If hand sharpening seems daunting, consider using a Dremel Tool or a Diamond Blade on a table saw for faster results.

A Dremel tool can be equipped with attachments for grinding, which can help sharpen circular saw blades. This method requires a steady hand and experience to maintain the correct grinding angle. It’s a great option for those who don’t have the time for manual sharpening but still want an efficient result.

For carbide-tipped blades, a diamond blade on a table saw is effective. Make sure the diamond blade is thinner than the gullets of the saw blade. This method is quick and efficient but requires more equipment and expertise. The diamond blade sharpens carbide tips by grinding them down to their optimal cutting edge.

If you prefer not to sharpen the blade yourself, professional services are available. They use specialized equipment to restore blades to factory quality. The advantage of professional sharpening is the precision that comes with using industrial machines designed to maintain proper angles and sharpness. Prices vary based on blade size and tooth count, generally ranging from $15 to $40.

Many professional sharpening services also offer to re-coat blades with special coatings like Teflon or titanium, which can further increase the longevity and performance of your saw.

The frequency of sharpening depends on how often you use the blade and the types of materials you're cutting. In general:

Light Usage: Sharpen the blade every 20 to 30 hours of use.

Heavy Usage: Sharpen the blade every 10 to 15 hours of use, especially when cutting through hardwoods or composite materials.

To avoid damaging the blade, inspect it regularly for signs of dullness or damage and sharpen it as needed. Regular maintenance is key to ensuring your saw cuts cleanly and smoothly.

Alongside sharpening, there are other steps you can take to maintain the sharpness and efficiency of your circular saw blade:

Clean the blade after each use to remove any sap, resin, or debris that might accumulate during cutting. This buildup can cause the blade to dull prematurely. A simple wire brush and acetone or a dedicated blade cleaner can help remove any buildup.

After cleaning, apply a small amount of lubricant or silicone spray to the blade. This helps prevent rust, reduces friction, and prolongs the life of your blade.

Regularly inspect the blade for chips, cracks, or bent teeth. These signs of damage may not always be visible during routine use, but they can significantly affect the blade's performance and safety. Replace any blades with significant damage to avoid accidents.

Sharpening a circular saw blade can significantly extend its lifespan and improve its performance. Whether you choose to do it by hand or seek professional services, maintaining a sharp blade is essential for safety and efficiency. Regular cleaning, lubrication, and inspections will help ensure your saw operates at its best.

Now that you know how to sharpen a circular saw blade, take action and ensure your tools are always ready for the task at hand. With proper care and sharpening, your circular saw will continue to perform effectively, making your woodworking and construction projects smoother and more efficient.

A: Signs include slower cutting, vibrations, poor cuts, and smoke or burn marks on the material being cut.

A: Yes, you can sharpen steel-toothed blades at home using a file, but carbide-tipped blades should be professionally sharpened.

A: You'll need a bench vice, sharpening sticks or sandpaper, files, and oil or lapping fluid.

A: Sharpen every 10-20 hours of use, depending on the materials you're cutting and blade condition.