T: +86-186-8927-7942

E: kemp@hangjin-machinery.com

E: kemp@hangjin-machinery.com

No. 107 Changning Road, Tongjing Town, Jiangning District, Nanjing, Jiangsu, China

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

Choosing the right circular blade can make or break your project. Are you using the best blade for your needs? Circular blades come in various types, each suited for different materials and tasks. In this post, you'll learn how to select the perfect blade for your project, ensuring precision, efficiency, and safety.

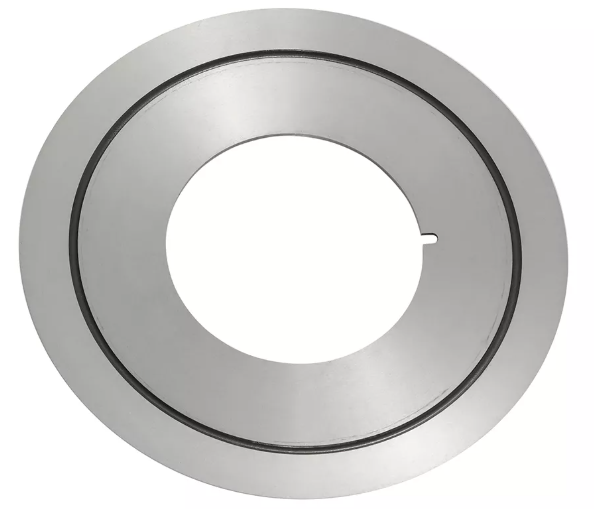

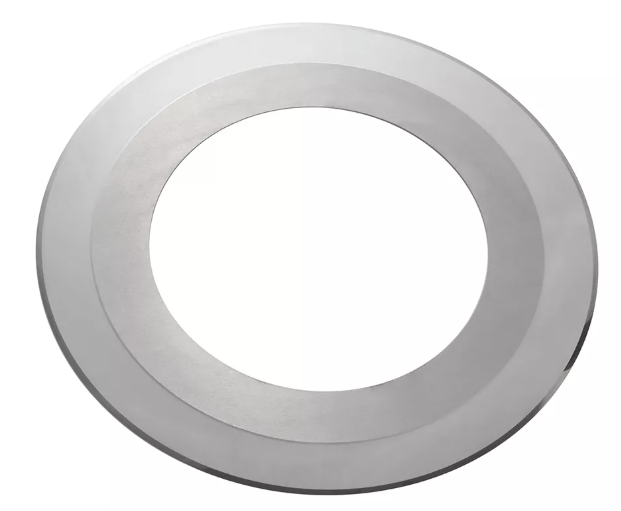

Circular blades are round cutting tools designed to spin rapidly on power saws, slicing through various materials. They come with sharp teeth or abrasive edges that cut cleanly and quickly as the blade rotates around its center. You’ll find them on tools like circular saws, miter saws, and table saws. Their design lets them handle a wide range of materials, from wood and plastic to metal and concrete, depending on the blade type.

Circular blades vary mainly by their material, tooth design, and intended use. Here are the common types:

Carbide-Tipped Blades: These blades have tungsten carbide tips on each tooth, making them extremely durable and sharp. They stay sharp much longer than steel blades and are perfect for cutting hardwoods and tough materials. They resist heat and wear, ideal for professional woodworking.

High-Speed Steel (HSS) Blades: Made entirely from steel, these blades are less expensive but dull faster. They suit softer materials and light-duty tasks, often used by DIYers or for occasional jobs.

Diamond Blades: These feature industrial diamonds bonded to the edge, allowing them to cut through very hard materials like concrete, stone, and tile. They often require water cooling to prevent overheating.

Rip Blades: Designed for cutting along the grain of wood, rip blades have fewer teeth with deep gullets to clear sawdust quickly. They cut fast but leave a rougher edge.

Crosscut Blades: These have more teeth for smoother cuts across the wood grain, producing clean edges with minimal splintering.

Combination Blades: Also called universal blades, they balance teeth types to handle both ripping and crosscutting reasonably well. They’re handy if you want to avoid switching blades often.

Circular blades offer several advantages:

Versatility: They come in many types, tailored for different materials and cuts. This flexibility makes them useful for a wide range of projects.

Precision: With the right blade, you get clean, accurate cuts that improve the quality of your work.

Efficiency: Circular blades spin at high speeds, allowing for quick cutting and less effort.

Durability: Especially carbide-tipped and diamond blades last long, reducing the need for frequent replacements.

Portability: Circular saws with these blades are handheld and easy to maneuver, letting you work on-site or in tight spaces.

Understanding these basics helps you pick the right blade to match your project’s needs, ensuring safer operation and better results. It’s always smart to match blade type, tooth design, and material compatibility to your specific cutting task.

When selecting a circular blade for your project, several important factors influence the blade's performance and suitability. Paying attention to these ensures you get clean cuts, efficiency, and safety.

First, consider the material you will cut. Different blades suit different materials:

Wood: Use blades designed for wood, often carbide-tipped for durability.

Metal: Requires blades with fine teeth and special coatings to resist heat.

Masonry and Concrete: Diamond blades are best since they cut through tough, abrasive materials.

Plastic and Laminate: Blades with a high tooth count and special tooth geometry help avoid chipping.

Matching blade type to material prevents damage to both blade and workpiece, ensuring better cuts and longer blade life.

The blade's diameter must fit your saw. Using the wrong size can be dangerous and damage the tool. Common diameters include:

165mm to 190mm: Typical for handheld circular saws.

254mm (10 inches): Common for table saws and miter saws.

Larger sizes (up to 350mm): Used in sliding table saws or heavy-duty equipment.

Always check your saw's specifications for compatible blade sizes. Using the correct diameter guarantees safe operation and optimal cutting depth.

The number of teeth affects cut speed and finish quality:

Fewer Teeth (16-40): Rip blades cut quickly along the grain but leave a rougher edge.

More Teeth (60-80+): Crosscut blades produce smoother cuts across the grain with less tear-out.

Combination Blades: Balance teeth types for versatile use, good for both ripping and crosscutting.

Tooth shape and angle also matter. For example, flat top teeth excel at ripping, while alternating top bevel teeth provide cleaner crosscuts. Choose tooth design based on your cut type and material.

Kerf is the width of the cut the blade makes. It relates directly to blade thickness:

Thin Kerf Blades: Remove less material, reduce waste, and require less power. Ideal for portable saws and softer materials.

Thicker Blades: More durable, resist bending during heavy-duty cuts, suitable for dense hardwood or professional table saws.

A wider kerf means a wider cut, which can waste material and demand more saw power. Balance kerf width against your saw's power and project needs.

Choosing the right circular blade means understanding the different types available and what each is best for. Let's break down the main blade types and their common uses.

These blades feature tungsten carbide tips welded to each tooth. That makes them incredibly tough and long-lasting. They stay sharp much longer than steel blades, which means fewer blade changes and cleaner cuts. You’ll find carbide-tipped blades perfect for hardwoods, plywood, and MDF. They handle tough materials without dulling quickly, making them a favorite among professionals and serious DIYers alike.

Best for: Hardwood, softwood, plywood, MDF, laminates

Advantages: Long-lasting sharpness, heat resistance, precise cuts

Example use: Cutting oak boards for furniture or cabinetry

Made entirely from steel, these blades are more affordable but dull faster. They're lighter-duty and work well for softer materials or occasional use. HSS blades suit hobbyists or DIY projects where cost is a concern and cutting demands aren’t heavy.

Best for: Softwood, light-duty cuts, occasional use

Advantages: Low cost, good for simple tasks

Limitations: Shorter lifespan, dulls quickly compared to carbide

Diamond blades have industrial diamonds embedded on the edge. This gives them the power to cut through extremely hard materials like concrete, stone, tile, and masonry. They often need water cooling to prevent overheating during use. Diamond blades are specialized tools mostly used in construction or remodeling projects involving tough surfaces.

Best for: Concrete, masonry, stone, tile

Advantages: Cuts hardest materials, long-lasting in abrasive conditions

Note: Requires wet cutting or cooling during use

These blades differ mainly by tooth count and design, affecting how they cut wood.

Rip Blades:

Fewer teeth (16-40)

Deep gullets to clear sawdust quickly

Cut along the grain (ripping)

Fast cuts but rougher edges

Ideal for breaking down lumber into smaller pieces

Crosscut Blades:

More teeth (60-80+)

Shallower gullets for smoother cuts

Cut across the grain

Produce clean edges with minimal splintering

Perfect for finish work or precise cuts

Many blades combine features of both, called combination or general-purpose blades, designed for versatility. But for best results, use dedicated rip or crosscut blades for their specific tasks.

Selecting the right circular blade depends heavily on the project type. Different materials and tasks demand blades designed to deliver the best performance and finish. Below, we explore how to choose blades for common project categories.

Wood projects often require precision and clean cuts. Carbide-tipped blades are the go-to choice here. They stay sharp longer and handle hardwoods, softwoods, plywood, and MDF with ease. For ripping lumber—cutting along the grain—use rip blades with fewer teeth (around 24 to 40). They cut faster but leave rough edges, perfect for breaking down wood quickly.

For crosscutting—cutting across the grain—choose blades with more teeth (60 to 80+) like crosscut blades. These provide smooth, splinter-free edges ideal for finish work, cabinetry, or furniture. Combination blades offer versatility if you want one blade for both ripping and crosscutting, but dedicated blades deliver better results.

Metal cutting requires blades that differ from wood blades. High-speed steel (HSS) blades or specialized carbide-tipped metal blades work best. These blades have fine teeth and special coatings to resist heat buildup and prevent warping. When cutting metals like aluminum, brass, or steel, use blades with a high tooth count and negative hook angles to reduce binding and improve control.

For tougher metals or thicker stock, consider blades designed specifically for metal cutting. They ensure cleaner cuts and prolong blade life. Remember, metal cutting often produces sparks and heat, so safety gear and proper blade choice are crucial.

Cutting masonry, concrete, or stone requires diamond blades. These blades feature industrial diamonds embedded on the edge, making them incredibly hard and durable. They can slice through tough materials that wood or metal blades cannot handle.

Diamond blades come in segmented or continuous rim designs. Segmented blades are great for fast, rough cuts in concrete or brick, while continuous rim blades provide smoother cuts for tile or stone. Wet cutting with water is often necessary to cool the blade and reduce dust.

If you’re a DIY enthusiast, you might prefer combination blades for general tasks. They reduce the need to switch blades frequently and handle a variety of cuts reasonably well. High-speed steel blades offer a budget-friendly option for occasional projects but dull quickly.

Professionals benefit from investing in specialized blades tailored to each task. Carbide-tipped blades for woodworking, metal-specific blades, and diamond blades for masonry improve efficiency, cut quality, and tool longevity. Professionals also tend to maintain multiple blades to match every project’s demands precisely.

Safety is key when working with circular blades. Always wear protective gear — safety glasses, gloves, and hearing protection. Never operate a saw without its blade guard in place. Keep your hands clear of the blade path and maintain a firm grip on the saw during cuts.

Before starting, check that the blade is properly installed and tightened. A loose blade can wobble, causing poor cuts or accidents. Make sure the blade matches your saw’s specifications, including diameter and arbor size.

Avoid forcing the blade through material. Let the blade do the work at its own pace. Forcing can cause kickback, where the saw jerks back suddenly, risking injury. Always stand to the side of the cut line, not directly behind the blade.

Use clamps or a stable surface to secure your workpiece. This prevents movement that could cause the blade to bind or the material to kick back.

Keeping your blade clean and sharp extends its life and ensures smooth cuts. Resin, pitch, and sawdust can build up on teeth, reducing cutting efficiency. Clean blades with a gentle solvent or commercial blade cleaner regularly.

Sharpen blades when you notice rough cuts, burning, or excessive effort during cutting. Carbide-tipped blades can be sharpened by professionals or with specialized sharpening tools. High-speed steel blades are easier to sharpen at home but dull faster.

Inspect blade teeth for damage or missing tips. Damaged teeth can cause vibration, poor cuts, and increase the risk of kickback. Replace blades that show excessive wear or damage.

Lubricate your saw’s moving parts as recommended by the manufacturer to keep the tool running smoothly and reduce strain on the blade.

Recognizing when a blade needs replacement is vital for safety and performance. Watch for these signs:

Dull Teeth: Cuts become slower, and the blade may burn wood or leave rough edges.

Missing or Chipped Teeth: Causes uneven cuts and vibration.

Blade Warping: Visible wobble during rotation, leading to unsafe operation.

Excessive Noise or Vibration: Indicates imbalance or damage.

Burn Marks on Material: Suggests blade is dull or dirty.

Increased Effort: If you need more force to cut, the blade likely needs attention.

Using a worn blade risks damaging your material, your saw, and yourself. Replace blades promptly to maintain safety and cut quality.

Choosing the right circular blade involves understanding material compatibility, blade size, tooth count, and kerf width. These factors ensure cleaner cuts, efficiency, and safety. For woodworking, opt for carbide-tipped blades; for metal, use high-speed steel or specialized blades; and for masonry, diamond blades are ideal. Regular maintenance and recognizing wear signs are crucial for optimal performance. Nanjing Hangjin Machinery Equipment Co., Ltd. offers high-quality blades that enhance project outcomes, providing durability and precision for various cutting tasks.

A: Circular blades are used for cutting various materials like wood, metal, and concrete with power saws.

A: Carbide-tipped blades are more durable and stay sharp longer, while high-speed steel blades are cheaper but dull faster.

A: Diamond blades can cut through hard materials like concrete and stone due to their industrial diamond edges.

A: Always wear safety glasses, gloves, and hearing protection.